7300 FOAMING PLASTIC MASTERBATCH

|

7300 FOAMING PLASTIC MASTERBATCH

|

||||||||||||||||

|

A Most Widely used Nitrogen foaming Masterbatch For Foamed Plastics

|

||||||||||||||||

|

Introduction- Foaming plastic masterbatch 7300 is particularly adapted for use in unicellular procducts where low gas loss be diffusion is required since it blows by releasing nitrogen.It is non-odorous in itself and imparts no odor to the finished products for which it is used and may be used in white or light colored compounds without the objectionable discoloration and staining obtained with many organic chemicals although it is a yellow pellet, the decomposition residue by heat is white. 7300 is broadly used blowing agent for most polymers processing, and should not be used with beryllium or copper tooling in injection molding structural foam. PRODUCT DESCRIPTIONS --

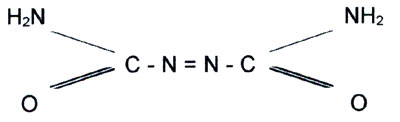

Chemical Composition: Azodicarbonamide (Azobisformamide)

STORAGE STABILITY AND WASTE DISPOSAL-- Foaming Plastic Masterbatch 7300 has good storage stability and will remain in a good condition provided it is kept dry, cool and away from any sources of heat close to decomposition temperature(190℃). 7300 should also be kept away from strong alkalis with which it reacts .Dispose of approved chemical disposal area. |